Tensile Fabric Structure Cost

March 06, 2026 By admin

7 Factors That Impact the Cost of Tensile Fabric Structures

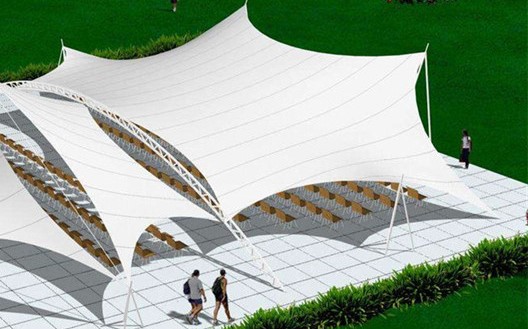

Various applications of tensile fabric structures include architectural enhancements together with temporary event venues. Measuring the exact financial expense of tensegrity fabric structures demands a comprehensive assessment. Before beginning a tensile fabric project, developers must know how different price factors impact project expenses.

Here are 7 key factors that impact the tensile fabric structure cost:

Size and Complexity:

The main cost drivers behind tensile fabric structures consist of finished size dimensions and architectural intricacy. Since larger designs need extended materials and workforce, they result in increased costs.

The duration of electrical design and industrial fabrication processes increases when constructing complex structures featuring intricate curves and angles, raising financial expenses.

Fabric Type and Grade:

Fabric selection serves as a major determinant of product cost. The price of high-performance fabric materials increases due to their combined attributes of superior strength and durability along with weather resistance properties such as PTFE, PVC, and ETFE.

Aside from fabric grade, the choice of material is a key determinant of total costs. Fabric prices will increase as manufacturers use high-quality materials to provide broader protection against UV rays, improved flame retardancy, and better resistance to tearing.

Frame Material and Design:

Overall construction costs depend heavily on the selection of frame materials, such as steel, aluminum, or wood, together with their specific design characteristics.

Steel remains the most budget-friendly option among frame materials, but aluminum provides an ideal combination of strength and weight properties for structures.

The deployment of elaborate frame structures with numerous connections and additional support elements drives up total costs.

Foundation and Ground Conditions:

Selection of the foundation structure depends on both ground conditions and the size and weight of the structure.

Complex soil conditions that incorporate soft terrain or rocky grounds will lead to foundation solutions that cost more.

Customization and Finishes:

Combining distinctive finishing techniques, such as customized coatings or printing, with unique color schemes and fabric patterns will increase construction expenses for tensile fabric structures.

The total cost increases when an owner integrates lighting fixtures along with sound systems and complementary features.

Engineering and Design Fees:

Engineering design fees represent a major component of the building expenses.

Labor Costs:

Labor expenses for fabrication, alongside the installation of structures and their maintenance, depend on various circumstances, including worksite location and complexity of design, together with skilled workforce accessibility.

Conclusion

Costs associated with tensile fabric structures depend on multiple important variables. By studying these key elements throughout the planning and design phases, you can develop cost allocations that match your goals.